AOI is a very important QC process of checking SMT soldering quality.

Fumax has strict control on AOI. ALL 100% boards are checked by AOI machine at Fumax SMT line.

AOI, with full name of Automated Optical Inspection, is a tool we use to detect circuit boards we provide customers with high-quality.

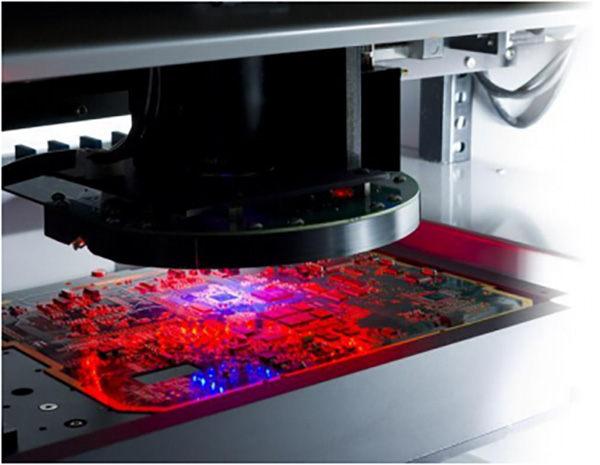

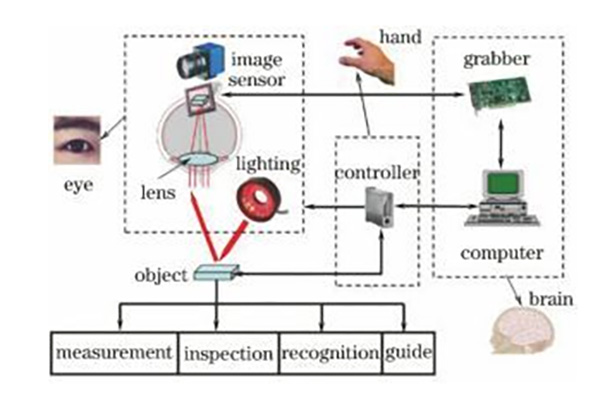

As a new emerging testing technology, AOI mainly detects common defects encountered in soldering and mounting based on high-speed and high-precision visual processing technology. The function of the machine is to scan the PCB automatically through the camera, collect images and compare with parameters in database. After image processing, it will mark the defects checked out and display on monitor for manual repair.

What to be detected?

1. When to use AOI?

The early use of AOI could avoid sending bad boards to subsequent assembly stages, achieving good process control. Which reduce repair costs, and avoid scrapping non-repairable circuit boards.

Ranking AOI as the last step, we could find all assembly errors such as solder paste printing, component placement, and reflow processes, providing a high level of security.

2. What to be detected?

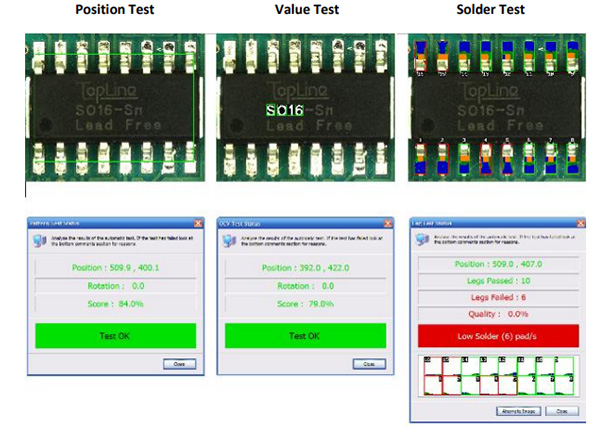

There are three mainly dimensions:

Position test

Value test

Solder test

The monitor will tell maintenance staff if the board is correct and mark where should be repaired.

3. Why we choose AOI?

Compared with visual inspection, AOI improves error detection, especially for those more complex PCB and larger production volumes.

(1) Precise location: As small as 01005.

(2) Low cost: To improve the pass rate of PCB.

(3) Multiple inspection objects: Including but not limited to short circuit,broken circuit, insufficient solder, etc.

(4) Programmable lighting: Increase image shrinkage.

(5) Network-capable software: Data collection and retrieval by text, image, database or a combination of several format.

(6) Effective feedback: As reference for parameter modifying before next manufacturing or assembly.

4. The Difference between ICT & AOI?

(1) ICT relies on the electrical characteristics of the electronic components of the circuit to check. The physical characteristics of the electronic components and the circuit board are detected by the actual current, voltage, and waveform frequency.

(2) AOI is a device that detects common defects encountered in soldering production based on the optical principle. The appearance graphics of circuit board components are inspected optically. Short circuit is judged.

5. Capacity: 3 Sets

To sum up, AOI could check the quality of boards coming out from the end of the production line. It plays an effective and accurate role in inspecting electronic components and PCB to ensure that products are of high quality without affecting production line and PCB manufacturing failures.